Swing coil feeders are generally used for circular blanking, especially in new energy industry to make the shell for battery. To maximize the production efficiency, the coil that are usually wide and thin, some with high requirements for flatness, so they need to go through a leveling device to be straightened before entering the swing feeder. However, some customers want to combine the leveling machine with the swing feeder due to space limit. This not only reduces the space required for the machine but also reduces the extra cost for a separated leveling machine. In response to this demand, we have designed a swing feeder with leveling function, which consists of a decoiler and a leveling swing feeder, enabling the material to be straightened while feeding.

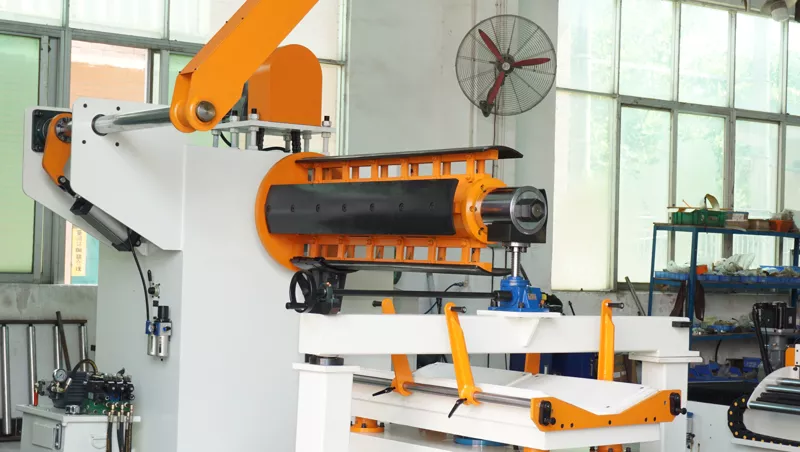

This model is our NCF-1300P with leveling function, suitable for wide coil maximum sheet width up to 1300mm. It integrates functions like decoiling, leveling and swing feeding. It can handle coil sheet with a thickness of less than 2.0mm and the loading capacity up to 10 tons.

The leveling rollers adopt a structure of upper three and down four rollers, combined with one set of feeding rollers at both inlet and outlet for precise feeding. The surface of feeding rollers is also treated with low-ploughing sandblasting and hard chrome plated, effectively increasing the friction between the material and the rollers to ensure that there is no slipping during feeding process, thus achieving high precision feeding.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.